LASER TEXTURING

Our head office WORLD ETCHING in Japan has introduced 5-axis laser processing machine (GF Machining Solutions). This is an engraving technology that uses laser light, and digital processing for everything from 3-axis to 5-axis processing. Texture processing, engraving, marking, fine processing, etc. can be efficiently reproduced not only on 2D planes but also on 3D curved surfaces, making it possible to draw points and lines as small as 30μm.

By introducing 5-axis laser processing machine, you can expand new possibilities of mold design. This machine is owned by many factories in our group, such as the NIHON ETCHING in Japan and China, CUSTOM ETCH in USA, and KRUTH in Germany.

Advantages of Laser Texturing

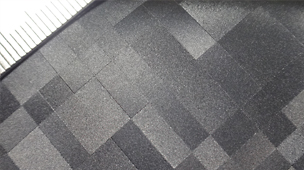

No seams and misalignment

Eliminates pattern switching lines and joints that occur in conventional etching processes.

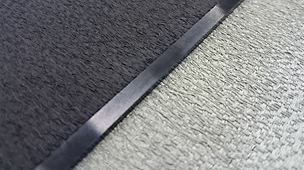

Machining position can be managed

By reliably managing the processing position, it becomes possible to match patterns.

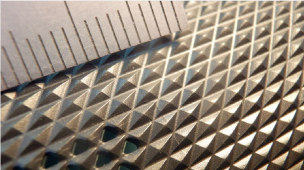

The cross-sectional shape of unevenness can be managed

Various cross-sectional shapes can be handled, and layout management is also possible.

Precision machining possible

Fine grains that could not be processed by etching can be processed.

Smooth depth change

It is possible to change the depth by

adjusting the density of the image data.

High reproducibility

By maximizing the high precision and high definition that are the characteristics of lasers, it is possible to develop complex patterns.