Equipment summary

In our mold maintenance business, we accept a variety of molds regardless size and the presence or absence of texture. We have earned the trust of many customers by making use of the extensive knowledge and solid technical skills of our veteran staff, and the experience of performing numerous difficult repairs.

| Overhead crane | 15t/10t | 1 unit |

| 15t/7.5t | 1 unit | |

| 5t/5t | 1 unit | |

| 1t | 1 unit | |

| Die spotting press | 300t | 1 unit |

| Surface grinder | 1 unit | |

| Milling machine | 1 unit | |

| Lathe machine | 1 unit | |

| Argon welding machine | 1 unit | |

| DSI laser welding machine | 1 unit |

We can also handle NC machining and EDM at our partner company in Thailand.

Laser Welding

- It supports large to small molds and deep objects, and can weld up to the cutting edge of a cutter knife.

- Compared to other types of welding, there is less heat input and no preheating or postheating is required, and the welding range is smaller, which shortens the lead time for finishing work.

- Ideal for repairing PL scratches and pinholes.

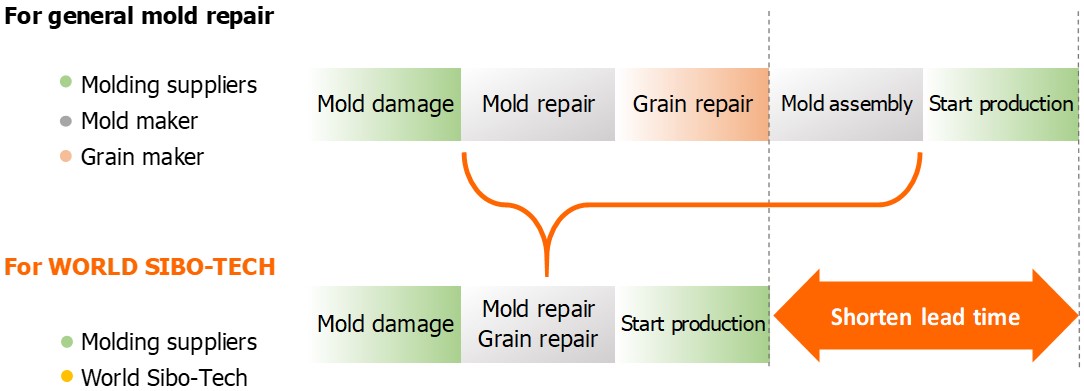

Integrated repair system

We can shorten the time to move the mold and reduce the transportation cost because we can do everything from mold repair to texturing repair by only one company.